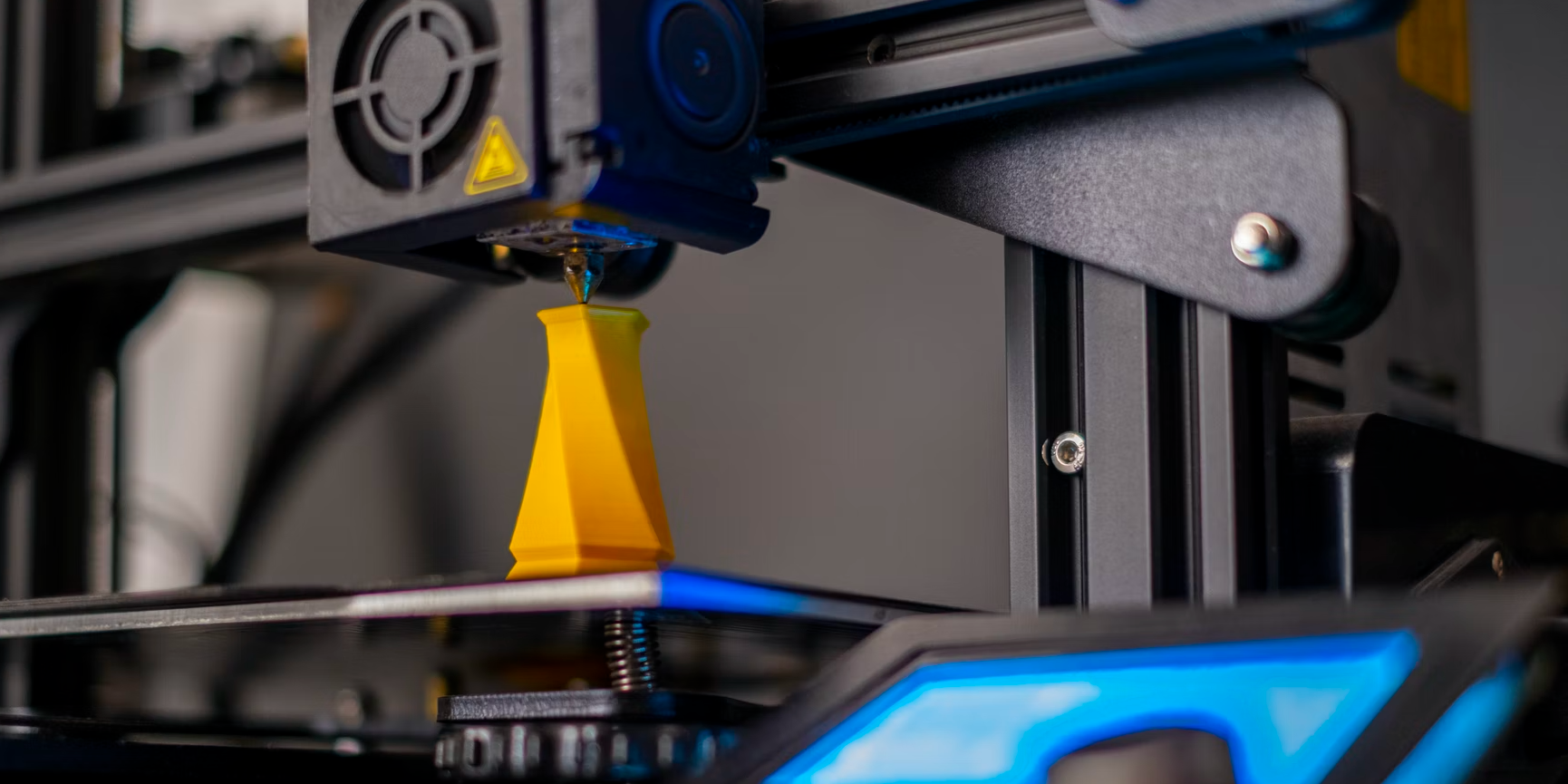

The Revolution of 3D Printing: Benefits, Applications, and Future Potential

3D printing, also known as additive manufacturing, has emerged as one of the most transformative technologies of the 21st century. By layering materials to create three-dimensional objects, this innovation has disrupted industries ranging from healthcare to aerospace. With advancements in materials, techniques, and applications, 3D printing is no longer limited to prototypes but is now driving real-world solutions. This article delves into the latest developments in 3D printing, showcasing its benefits, applications, and future potential with examples and case studies.

1. Advancements in Materials for 3D Printing

The Shift to Sustainable Materials

The demand for environmentally friendly manufacturing processes has led to the development of biodegradable and sustainable materials for 3D printing. Plant-based resins and biodegradable polymers, such as PLA (Polylactic Acid), are increasingly being adopted, especially in consumer products and packaging industries.

Example:

A startup in Europe recently launched a line of biodegradable coffee pods made entirely from 3D-printed materials. These pods decompose naturally, reducing environmental waste.

Metal Alloys and Composites

High-strength metal alloys, such as titanium and stainless steel, are being widely used in industries requiring durability and precision. Composite materials like carbon-fiber-infused polymers add strength while keeping components lightweight.

Case Study:

GE Aviation used 3D printing to manufacture fuel nozzles for its LEAP jet engine. By combining metal alloys, the company reduced the number of components in the nozzle from 20 to 1, cutting weight by 25% and increasing durability.

Bioprinting Breakthroughs

Bioprinting uses bioinks—gel-like substances containing living cells—to create human tissues and organs. This advancement is pushing the boundaries of regenerative medicine, offering hope for patients waiting for organ transplants.

Example:

Researchers at Tel Aviv University bioprinted a miniature, functional heart using human cells. While not ready for transplantation, it demonstrates the potential of bioprinting in addressing organ shortages.

2. Applications in Healthcare

Customized Prosthetics and Implants

One of the most impactful uses of 3D printing in healthcare is the ability to create custom-fit prosthetics and implants tailored to individual patients. Traditional manufacturing often struggles with personalization, but 3D printing makes this seamless.

Case Study:

In India, a young boy born without fingers received a fully functional prosthetic hand created using 3D printing. The total cost was less than $100, demonstrating the affordability and accessibility of the technology.

3D-Printed Medicines

The pharmaceutical industry is exploring 3D printing to produce customized medications. By layering active ingredients, companies can create pills with precise dosages and release mechanisms.

Benefit:

For patients with complex conditions requiring multiple medications, 3D-printed pills can combine several drugs into one, improving adherence and outcomes.

Tissue Engineering

3D-printed skin grafts are transforming treatment for burn victims. Additionally, organ scaffolds created using bioprinting techniques help regenerate damaged tissues.

Example:

A company in the US successfully printed synthetic skin for burn victims, reducing recovery time by 40%. This innovation is now being tested for use in reconstructive surgeries.

3. Emergence of AI-Driven 3D Printing

The integration of artificial intelligence (AI) with 3D printing has unlocked new possibilities, such as optimizing designs, improving production accuracy, and predicting potential failures.

Generative Design Tools

AI-powered software generates optimized designs that were previously unimaginable. These designs are not only structurally sound but also lightweight, which is critical in industries like aerospace.

Example:

Airbus used AI and 3D printing to redesign partition panels in its A320 aircraft. The result was a 45% reduction in weight, leading to significant fuel savings.

Predictive Maintenance

AI algorithms monitor 3D printing processes in real time, identifying issues such as material inconsistencies or temperature fluctuations. This reduces waste and ensures higher quality output.

4. Mass Customization in Manufacturing

3D printing has transformed manufacturing by enabling mass customization—producing items tailored to individual preferences at scale. This capability is revolutionizing industries like fashion, jewelry, and consumer electronics.

Fashion and Footwear

Major brands are leveraging 3D printing to create custom-fit products.

Example:

Adidas launched its Futurecraft 4D shoe line, featuring midsoles made with 3D printing. Each pair is tailored to the customer’s foot shape and movement pattern, offering unmatched comfort and performance.

Consumer Goods

3D printing allows small businesses to produce customized goods on demand, eliminating the need for large inventories.

Benefit:

This on-demand model reduces waste and lowers storage costs, making manufacturing more sustainable and cost-effective.

5. Affordable 3D Printing for Consumers

As the cost of desktop 3D printers drops, hobbyists, educators, and small businesses are embracing the technology for various applications. From DIY projects to small-scale manufacturing, the accessibility of 3D printing is driving innovation.

Example:

A teacher in Canada used a $200 3D printer to create educational tools for visually impaired students, including tactile maps and braille learning aids.

Benefit:

Affordable printers empower individuals to innovate and solve local problems without relying on large-scale manufacturing.

6. Regulatory and Ethical Challenges

While 3D printing offers immense benefits, it also poses regulatory and ethical concerns. The ability to create complex objects, including firearms, has sparked debates around control and oversight.

Intellectual Property Concerns

The rise of open-source 3D models has led to intellectual property disputes. Companies are now exploring digital rights management (DRM) solutions to protect their designs.

Example:

A major automotive company recently filed a lawsuit against a third party for unauthorized reproduction of car parts using 3D printing.

Healthcare Regulations

Medical applications of 3D printing must adhere to stringent safety standards to ensure patient safety. Regulatory bodies like the FDA are working to establish clear guidelines.

7. Space Exploration and 3D Printing

Space agencies and private companies are leveraging 3D printing to address the challenges of manufacturing in space. Printing components on-site reduces the need to transport heavy tools and materials.

Example:

NASA successfully tested a 3D-printed rocket engine injector that performed better than traditionally manufactured parts. This achievement underscores the potential of 3D printing for deep-space exploration.

In-Situ Manufacturing

The ability to 3D print objects in space is critical for long-term missions. Astronauts on the International Space Station have already printed tools and spare parts on demand.

Future Potential:

As humanity looks to establish colonies on Mars and the Moon, 3D printing will play a vital role in constructing habitats using locally sourced materials.

Conclusion

3D printing is revolutionizing industries with its versatility, cost-effectiveness, and ability to create customized solutions. From healthcare and aerospace to fashion and consumer goods, the technology is driving innovation and sustainability. However, as 3D printing continues to evolve, addressing regulatory and ethical challenges will be crucial to ensuring its safe and responsible use. With advancements in materials, AI integration, and applications in space exploration, the future of 3D printing holds limitless possibilities. Businesses and individuals alike must embrace this technology to stay ahead in an increasingly competitive and dynamic world.