Introduction

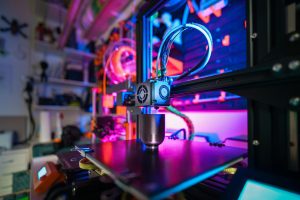

Recently, I sat down with Joanne Moretti, CRO at Fictiv, to explore the continuously evolving 3D printing market. Joanne shared her perspective on the significant shifts in this fast-paced technology and its evolving role across various stages of the product lifecycle. Her insights reveal a future where stronger and more durable materials, faster and more accurate hardware, affordable pricing, and an expanding ecosystem of service providers will drive innovation and yield substantial business value. With industry giants like Apple reportedly integrating 3D printing in their production processes, the market is set for transformative changes. Let’s delve deeper into Joanne’s thoughts and the industries revolutionized by 3D printing.

Current Landscape of 3D Printing

Q: Joanne, what are you observing in the 3D printing sector right now?

The adoption of additive manufacturing, or 3D printing, in industrial applications is increasing. Recently, notable publications, including Yahoo!, have speculated about Apple’s interest in 3D printing parts for the Apple Watch. This is a significant milestone, illustrating the technology’s expanding capabilities beyond quick-turn, low-volume prototyping in early product lifecycle stages. Now, 3D printing is integral to testing, validation, and full production, supporting both part production and the creation of necessary manufacturing tools.

According to Fortune Business Insights, the industry’s Compound Annual Growth Rate (CAGR) is nearly 24.9%, valued at $22.4 billion in 2023 and projected to reach $105.99 billion by 2030. Our own Fictiv 2023 State of Manufacturing report shows that 94% of respondents face structural barriers slowing innovation. 3D printing is crucial for new product development and large-scale production, and its potential to accelerate development cycles and improve production efficiency is significant.

Industries Harnessing 3D Printing Technology

Q: Which industries are leveraging 3D printing for their parts?

3D printing is revolutionizing several industries, including consumer electronics, healthcare, automotive, aerospace, robotics, and manufacturing innovations. By utilizing materials such as plastics, metals, ceramics, and even human cells, these industries can produce vital components more quickly and at lower costs than ever before.

Healthcare: Revolutionizing Medical Solutions

Applications in Healthcare

In healthcare, 3D printing drives significant medical breakthroughs in bioprinting, replication, and prosthetics. This technology can potentially solve organ donation shortages, transform heart surgery, and create custom braces for chronic conditions like scoliosis.

Notable Innovations:

- The MIT Biorobotic Hybrid Heart: Developed by a team led by a mechanical engineering professor at MIT, this artificial heart is a 3D-printed replica that anatomically replicates the heart’s electromechanical function. Using CT or MRI scans, researchers convert heart images into 3D models and print them using a soft and flexible ink-based polymer. The heart’s pumping action is simulated by a system similar to blood pressure cuffs, allowing doctors to test implants like synthetic valves using the patient’s exact anatomy, thereby significantly reducing risk.

Future Prospects

Expect advancements in 3D-printed bone composite implants, larger 3D-printed vascular tissues, and 4D-printed shape-shifting components. These innovations promise to enhance healthcare solutions and reduce prototype lead times for invasive products.

Case Study: Fictiv assisted TransMed7 in rapidly prototyping biopsy tools, reducing new product introduction times from 10 years to 2 and saving millions in costs.

Aerospace: Pushing the Boundaries of Exploration

Applications in Aerospace

Pioneering companies like SpaceX and Blue Origin leverage 3D printing to accelerate aerospace product development and optimize performance. SpaceX utilized Direct Metal Laser Sintering (DMLS) for rocket engines, while Blue Origin uses friction stir additive manufacturing (FSAM) to 3D print with metals like aluminum and titanium.

Notable Innovations:

- 3D-Printed Helmets for Spacesuits: These helmets feature customized padding, integrated microphones, and pressure regulation valves, significantly enhancing astronaut safety.

- NASA’s Archinaut One Program: This initiative involves 3D-printing structures in space to assemble solar arrays, paving the way for in-space manufacturing of telescopes, antennae, and radar booms.

Future Prospects

The future of aerospace 3D printing will focus on improving production speed, material utilization, and cost efficiency. The integration of AI with 3D printing is an exciting development, particularly for 3D printing spare parts in space, demonstrating measurable cost savings and efficiency.

Education: Enabling Access and Innovation

Applications in Education

3D printing is transforming classrooms, from elementary schools to colleges like Purdue University, which offers 3D-printing courses and resources. Engineering students can print prototypes, architecture students can create 3D models, and chemistry students can produce 3D molecule sculptures.

Benefits:

- Enhanced Learning: 3D printing fosters problem-solving skills and deepens understanding of complex subjects through hands-on innovation.

- Custom Educational Aids: Teachers can create tailored educational tools and design challenges for students, enhancing the learning experience.

Future Prospects

3D printing’s greatest potential in education is improving access to quality learning. Maggie Grout’s Thinking Huts project uses concrete 3D-printing technology to build schools faster, addressing the global education crisis and promoting economic growth.

Manufacturing: Revolutionizing Production Processes

Applications in Manufacturing

Since the first 3D printing patent in 1984, high-tech industries have utilized this technology for rapid, efficient production. 3D printing supports creating replacement parts for CNC machines, custom solutions for manufacturing efficiency, and addressing supply chain issues exacerbated by COVID-19.

Key Advantages:

- Rapid Prototyping: Facilitates faster design iterations and improves product visualization.

- Supply Chain Solutions: Serves as an alternative parts source and supports efficient manufacturing operations.

Case Study: Fictiv helped Mira Labs quickly prototype AR glasses, enhancing their design process and shortening manufacturing cycle times using Multi Jet Fusion 3D printing.

Future Prospects

Anticipate increased adoption of 3D printing for production, development of hybrid CNC/3D printers, and advancements in 3D metal printing. These trends will further enhance manufacturing efficiency and innovation.

Automotive: Driving Advanced Manufacturing

Applications in Automotive

Automakers like Audi and innovators like Kevin Czinger are leveraging 3D printing for part production, from engine components to body parts. The ability to print lightweight, complex parts on demand offers significant benefits.

Key Developments:

- 3D-Printed Cars: Projects like the Light Cocoon demonstrate 3D printing’s potential in structural automotive components.

- Customization: 3D printing allows for affordable custom parts and design adjustments, currently limited to luxury vehicles.

Future Prospects

Expect broader adoption of 3D printing in automotive manufacturing, focusing on sustainability and renewable energy. The technology will likely enable mass-produced, fully 3D-printed cars and support electric vehicle production.

Robotics: Enhancing Precision and Flexibility

Applications in Robotics

3D printing offers cost-effective solutions for producing complex robotics parts, such as end-of-arm tooling (EOAT) and custom components. The combination of 3D printers and robotics enables the creation of intricate shapes and custom objects.

Innovations:

- On-Site Infrastructure: NASA’s 3D-printed housing unit initiative illustrates the potential for 3D printing infrastructure for future space colonies.

Future Prospects

3D printing will continue to revolutionize the robotics industry by enhancing production speed and flexibility. Fictiv’s partnership with HEBI Robotics demonstrates the technology’s ability to improve lead times and product quality.

Case Study: HEBI Robotics utilized Fictiv’s Multi Jet Fusion 3D printing to overcome quality and delay issues, enhancing speed and agility in their production processes.

Why Outsource 3D Printing?

Outsourcing 3D printing services can address challenges in sourcing high-quality parts and support custom prototype development. Digital manufacturers like Fictiv provide solutions to these barriers, enabling rapid prototyping and production of custom components.

FAQs on 3D Printing Transformations

1. What industries are seeing the most impact from 3D printing technology?

- Answer: The industries most impacted by 3D printing include healthcare, aerospace, education, manufacturing, automotive, and robotics. These sectors are leveraging 3D printing for rapid prototyping, efficient production processes, and innovative solutions.

2. How is 3D printing benefiting the healthcare industry?

- Answer: In healthcare, 3D printing drives medical breakthroughs in bioprinting, replication, and prosthetics. It enables the rapid production of customized medical instruments, implants, and even organ replicas, which significantly reduce risks and improve patient outcomes.

3. What are some exciting future trends in 3D printing for the aerospace sector?

-

- Answer: Future trends in aerospace 3D printing include optimizing production speed, material utilization, and cost reduction. One of the most promising developments is 3D printing components directly in space, which can revolutionize manufacturing for long-term space missions and infrastructure.