In recent years, advanced robotics has emerged as a transformative force across various industries, revolutionizing how businesses operate, improving efficiency, and enhancing productivity. From manufacturing to healthcare, agriculture to logistics, the integration of advanced robotic systems is reshaping workflows, optimizing processes, and enabling new possibilities. This article delves into the impact of advanced robotics on different industries, highlighting key benefits, notable case studies, and examples that illustrate their significant contributions.

Understanding Advanced Robotics

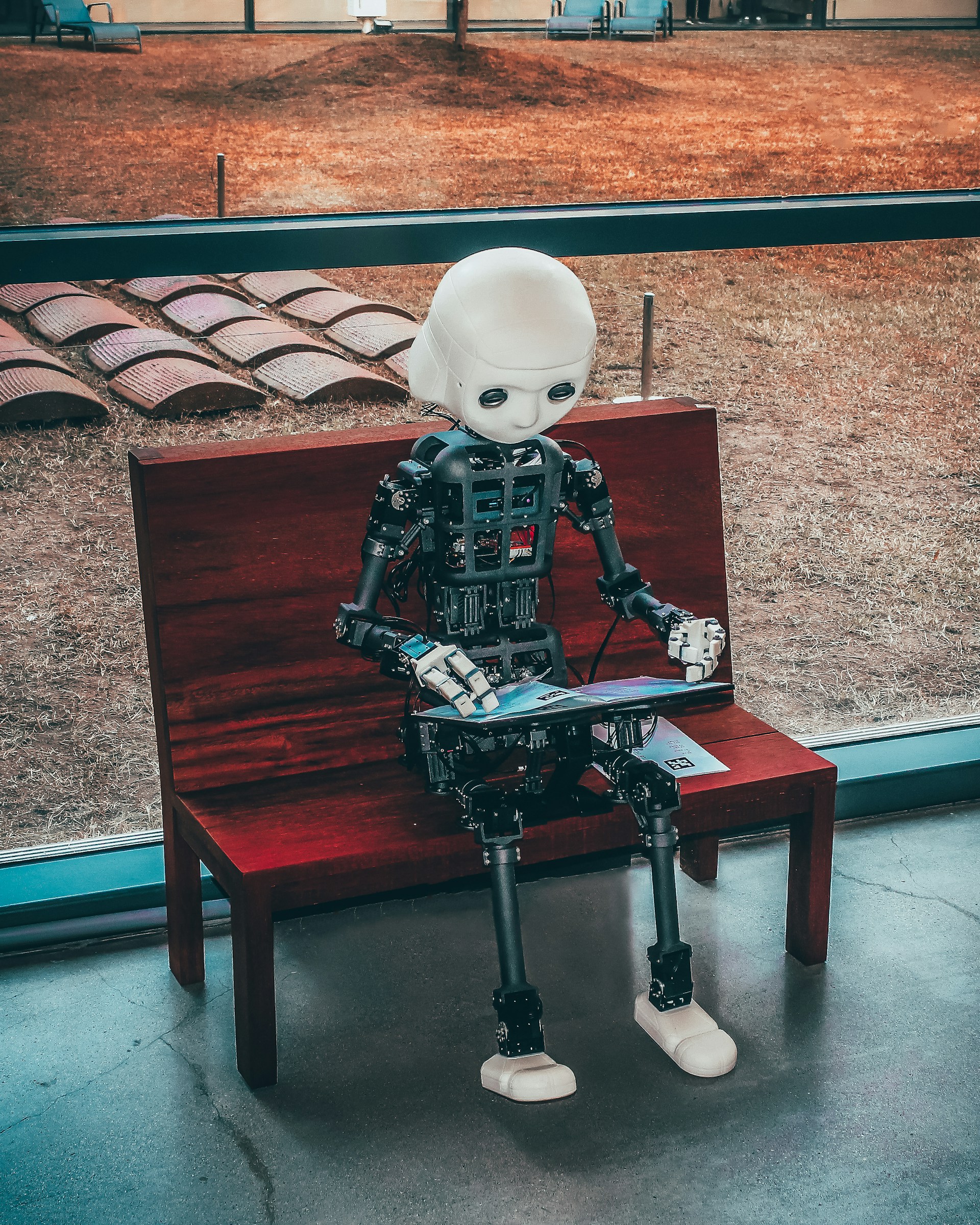

Advanced robotics refers to the use of highly sophisticated robots that are equipped with artificial intelligence (AI), machine learning, and sensory technologies. These robots are capable of performing complex tasks with precision and adaptability, making them suitable for a wide range of applications. Unlike traditional robots, which were often limited to repetitive tasks in controlled environments, advanced robotics can operate in dynamic settings, interact with humans, and make decisions based on real-time data.

Benefits of Advanced Robotics

- Increased Efficiency and Productivity

Advanced robotics can operate continuously without fatigue, leading to significant increases in efficiency. They can perform tasks faster and with greater accuracy than human workers, reducing cycle times and enhancing overall productivity. - Cost Reduction

Although the initial investment in advanced robotic systems can be substantial, they often lead to long-term cost savings. By reducing labor costs, minimizing errors, and optimizing resource allocation, businesses can achieve a quicker return on investment (ROI). - Improved Safety

Robotics can take on dangerous tasks, reducing the risk of workplace accidents. In industries such as construction and manufacturing, robots can perform hazardous jobs, thereby protecting human workers from potential harm. - Enhanced Quality and Consistency

Robots are designed to perform tasks with high precision, which improves product quality and consistency. This is particularly beneficial in industries where even minor variations can lead to defects. - Flexibility and Scalability

Advanced robotics can be programmed or trained to perform various tasks, allowing businesses to adapt quickly to changing demands. This flexibility enables companies to scale operations efficiently, responding to market trends without extensive downtime.

Case Studies of Advanced Robotics in Action

Manufacturing with ABB Robotics

ABB, a leader in industrial automation, has been at the forefront of integrating advanced robotics into manufacturing processes. One notable example is their collaboration with a major automotive manufacturer to automate assembly lines. By implementing ABB’s robotic arms equipped with machine vision and AI, the manufacturer significantly improved its production efficiency. The robots were able to perform tasks such as welding, painting, and assembling components with exceptional precision, reducing the time needed for each vehicle’s production. As a result, the plant saw a 30% increase in output and a 25% reduction in operational costs.

Healthcare Robotics at Intuitive Surgical

Intuitive Surgical’s da Vinci Surgical System exemplifies how advanced robotics is transforming healthcare. This robotic surgical platform allows surgeons to perform minimally invasive surgeries with enhanced precision and control. The system includes robotic arms, a 3D high-definition vision system, and intuitive controls that translate a surgeon’s hand movements into smaller, more precise movements of the instruments inside the patient.

The da Vinci system has revolutionized procedures such as prostatectomies and hysterectomies, leading to shorter recovery times and less postoperative pain for patients. Hospitals using the da Vinci system report higher patient satisfaction rates and improved surgical outcomes, showcasing the significant impact of advanced robotics in the medical field.

Agriculture and Precision Farming

In agriculture, advanced robotics is playing a crucial role in enhancing productivity and sustainability. Companies like Blue River Technology are pioneering the use of robotic systems for precision farming. Their “See & Spray” technology utilizes machine learning and computer vision to identify and target individual weeds in a field. Instead of spraying herbicides over an entire area, the robot applies chemicals only where needed, reducing chemical usage by up to 90%.

Farmers using this technology not only reduce costs associated with herbicide application but also minimize environmental impact, promoting sustainable farming practices. This case highlights how advanced robotics can address challenges in agriculture while improving efficiency and sustainability.

Examples of Advanced Robotics Applications

- Logistics and Warehousing

Companies like Amazon and Alibaba are leveraging advanced robotics in their logistics operations. Amazon’s Kiva robots, for example, navigate warehouses autonomously, transporting goods to fulfillment centers. This automation has significantly reduced the time taken to pick and pack orders, allowing for quicker delivery times. - Construction Robots

Construction firms are increasingly adopting robotics for tasks such as bricklaying and concrete pouring. Robots like the SAM (Semi-Automated Mason) can lay bricks at a rapid pace, improving the speed of construction projects while maintaining high-quality standards. - Robotic Exoskeletons in Industry

Robotic exoskeletons, such as those developed by Ekso Bionics, are being utilized in industries like manufacturing and construction to assist workers with heavy lifting. These wearable devices reduce the physical strain on employees, enhancing their productivity and reducing the risk of injury. - Service Robots in Hospitality

In the hospitality industry, robots like those from Savioke are being used to deliver room service in hotels. These service robots can navigate through hotel corridors, delivering items to guests without human intervention, improving operational efficiency and guest experience.

The Future of Advanced Robotics in Industries

The potential of advanced robotics is vast, and as technology continues to evolve, we can expect to see even greater advancements and applications. Here are some anticipated trends for the future:

- Integration with AI and Machine Learning

The synergy between advanced robotics and AI will lead to smarter systems capable of learning from their environment and improving their performance over time. This will enable robots to handle more complex tasks and make autonomous decisions. - Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human workers safely. The growth of cobots will facilitate greater human-robot collaboration in various industries, enhancing productivity while ensuring safety. - Customization and Personalization

As robotic technology becomes more accessible, businesses will be able to customize robotic solutions to fit their specific needs. This personalization will drive the adoption of robotics in smaller companies and diverse sectors. - Robotics in Developing Economies

Advanced robotics is expected to gain traction in developing economies, helping to address labor shortages and improve efficiency in industries such as agriculture and manufacturing. This could lead to economic growth and enhanced quality of life in these regions. - Ethical and Regulatory Considerations

As advanced robotics becomes more prevalent, ethical considerations and regulations will need to evolve. Issues such as job displacement, data privacy, and safety standards will be at the forefront of discussions around robotics in the workplace.

Challenges Facing Advanced Robotics

While advanced robotics presents numerous benefits, several challenges must be addressed:

- High Initial Investment

The cost of implementing advanced robotic systems can be a barrier for many businesses. Smaller companies may struggle to justify the initial investment, even if long-term savings are evident. - Skill Gap

The integration of robotics into industries requires a workforce skilled in operating and maintaining these systems. Companies may face challenges in finding qualified personnel, necessitating investment in training and education. - Technological Reliability

As with any technology, reliability is crucial. Businesses must ensure that their robotic systems are dependable and can operate in various conditions without frequent breakdowns. - Cybersecurity Risks

Advanced robotics systems are often connected to networks, making them vulnerable to cyberattacks. Ensuring the security of these systems is paramount to protect sensitive data and maintain operational integrity.

Conclusion

Advanced robotics is undeniably changing industries, providing significant benefits in efficiency, safety, and productivity. From manufacturing and healthcare to agriculture and logistics, the transformative power of robotics is evident in numerous case studies and examples. As we look to the future, the continued integration of AI, machine learning, and collaborative systems will further enhance the capabilities of robotics, offering exciting possibilities for businesses across sectors.

While challenges remain, addressing these issues through investment in technology, workforce training, and cybersecurity measures will be essential to harnessing the full potential of advanced robotics. As industries adapt to these changes, the future promises a landscape where robotics and humans work together to achieve greater heights of innovation and efficiency.