The Revolution in Manufacturing Is Here

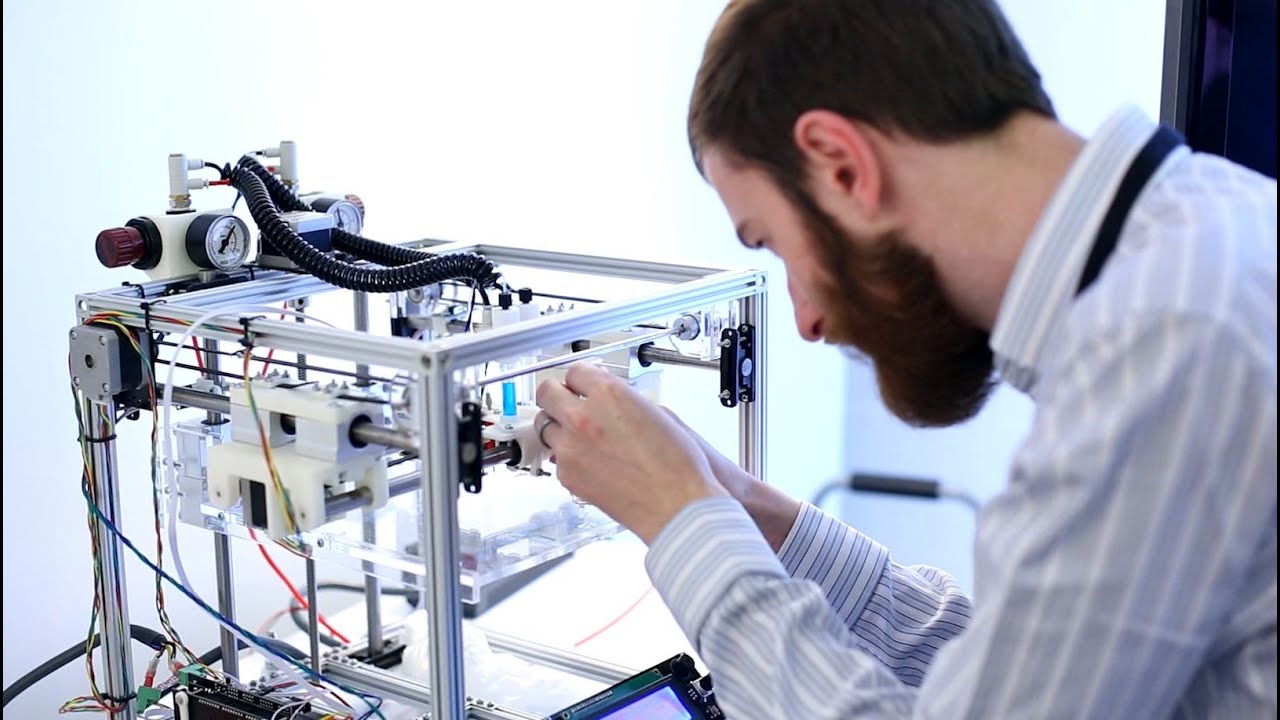

For decades, traditional manufacturing has been at the heart of numerous industries, including automotive, aerospace, and healthcare. While effective, the standard processes—machining, molding, and assembly—often involve time-consuming production cycles, high costs, and limited customization options. Enter 3D printing.

This groundbreaking technology, also known as additive manufacturing, is redefining how products are designed, produced, and delivered. By building objects layer by layer, 3D printing minimizes material waste, shortens production timelines, and unlocks new possibilities for customization and creativity.

The question isn’t whether 3D printing is going to change manufacturing—it already has. Instead, it’s about understanding how its rapid evolution is influencing global industries and what this means for businesses of all sizes. Whether you’re an entrepreneur, an engineer, or simply curious about the tech world, this post will walk you through the implications, benefits, limitations, and potential future of 3D printing in the manufacturing landscape.

Industries Transformed by 3D Printing

While 3D printing can and does make an impact across nearly every industry, a few key sectors are already leveraging its game-changing potential.

Healthcare

From prosthetics to surgical tools, the healthcare industry has embraced the customizability of 3D printing. One of the most revolutionary applications? Printing organs and tissue. Companies like Organovo are spearheading the creation of bio-printed living tissues for research and, eventually, transplantation. Dental professionals, too, are benefiting, printing custom braces, molds, and crowns quickly and efficiently.

Aerospace

The aerospace industry demands precision. 3D printing allows companies like GE Aviation to manufacture lightweight, highly complex engine parts with unparalleled accuracy. By reducing the weight of components, fuel efficiency improves, environmental impact decreases, and overall costs drop.

Automotive

Additive manufacturing is making waves in the automotive world, particularly in rapid prototyping and custom parts production. For example, Ford uses 3D printing to develop prototype parts in days, not months, which has significantly accelerated its design and production process. Niche sectors, such as motorsports, are also utilizing the technology to create highly customized performance-driven components.

Consumer Goods

Companies like Adidas and Nike are using 3D printing to create small-run footwear collections, focusing on customization and ergonomic designs. These products were once impossible to produce with traditional methods but are now achievable, cost-effective, and eco-friendly.

Why Businesses Are Investing in 3D Printing

1. Reduced Costs

Traditional manufacturing methods often involve extensive tooling and setup costs—especially for small production runs. With 3D printing, businesses can eliminate many of these expenses. For example, creating molds for injection molding can cost thousands, but in additive manufacturing, initial design files are all you need to begin production at a fraction of the cost.

2. Speed and Agility

Gone are the days of waiting months for product revisions or retooling processes. 3D printing enables rapid prototyping, allowing businesses to test and refine their products in days rather than months. This reduction in lead time translates into faster innovation and quicker responses to market demands.

3. Customization

From personalized consumer products to industry-specific components, 3D printing provides unparalleled levels of customization. Businesses can now offer tailor-made solutions without the additional costs traditionally associated with bespoke manufacturing.

4. Minimized Waste

Unlike subtractive manufacturing, where materials are removed through cutting or grinding, additive manufacturing builds layer by layer, using only the necessary material. This not only reduces waste but also increases sustainability—a critical consideration for many businesses today.

Case Studies of Impactful 3D Printing Applications

1. Prosthetics in Developing Countries

Volunteer organizations like e-NABLE use 3D printing to create low-cost prosthetic hands for children in developing countries. The cost? Just $50 per hand compared to thousands through traditional means.

2. Aerospace Advancements by Airbus

Airbus has incorporated over 1,000 3D-printed parts into its A350 XWB plane. These components have reduced production time and overall aircraft weight, leading to fuel savings and a reduction in CO2 emissions.

3. Nike’s Performance Footwear

Nike’s Vapor Laser Talon, a football cleat designed for optimal speed on the field, was created using 3D printing. By bypassing traditional manufacturing techniques, Nike was able to produce a lightweight, performance-driven design unavailable through traditional methods.

Current Challenges and Limitations

Despite its many benefits, 3D printing isn’t without challenges.

1. Material Constraints

While significant progress has been made, the range of materials that can currently be used in 3D printing is still limited. Industries requiring highly specialized materials may find this restrictive.

2. High Upfront Costs

Although long-term savings are significant, the initial investment—particularly for industrial-grade 3D printers—can be prohibitive for smaller businesses.

3. Scalability Issues

3D printing excels in small-batch prototypes and production but may struggle to match the efficiency and cost-effectiveness of traditional mass manufacturing processes for very high-volume production.

4. Intellectual Property Concerns

With digital design files being shared and recreated easily, ensuring designs remain secure and protected has become a growing concern.

The Future of 3D Printing in Manufacturing

The next decade promises exciting advancements in 3D printing technology and applications.

1. Material Advances

Research is underway to expand material options, including bio-based and recyclable alternatives. This will unlock opportunities for industries like fashion, construction, and beyond.

2. Integration with AI

AI and machine learning will further optimize 3D printing processes. From predicting structural weaknesses to automating design improvements, the synergy between AI and 3D printing will redefine what’s possible.

3. Distributed Manufacturing

Imagine a world where products are designed in one country, digitally transmitted across the globe, and produced locally within hours. This model of distributed manufacturing, enabled by 3D printing, could disrupt global supply chains and reduce production-associated emissions.

Tips for Businesses Looking to Leverage 3D Printing

New to 3D printing? Here’s how to get started.

- Start Small: Begin by identifying areas where 3D printing can make a measurable impact, such as prototyping or low-volume production.

- Consult Experts: Work with experienced 3D printing providers or consultants before investing in machinery and resources.

- Invest in Training: Ensure your team is equipped with the knowledge needed to operate and design for 3D printing effectively.

- Explore Partnerships: Partner with established 3D printing firms to explore its potential without committing significant capital upfront.

3D Printing Is Shaping the Future, One Layer at a Time

It’s clear that 3D printing isn’t just a passing trend—it’s a revolutionary force reshaping industries and redefining possibilities. From healthcare to aerospace, its impact is undeniable, and we’re only at the tip of the iceberg.

For businesses ready to innovate, 3D printing offers a path toward improved efficiency, higher ROI, and greater adaptability in a rapidly evolving market. Are you prepared to take your manufacturing processes to the next level?