Introduction

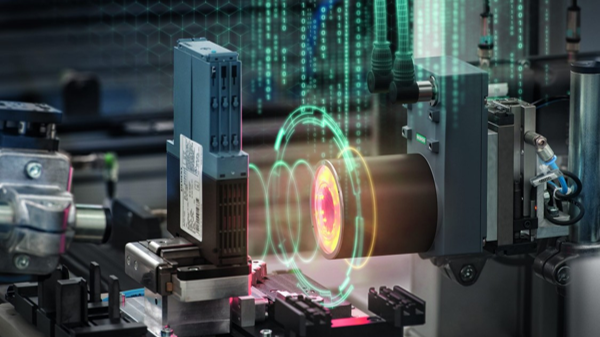

Prototyping serves as a pivotal bridge between innovative concepts and tangible products, particularly in the realm of optical device manufacturing. The journey from ideation to a finalized optical product involves numerous stages, each demanding precision, iteration, and seamless transitions. Optimizing these prototyping processes not only accelerates product development but also enhances efficiency, quality, and ultimately, the competitiveness of the final product in the market.

Understanding the Significance of Prototyping

Prototyping stands at the forefront of innovation, enabling designers and manufacturers to transform abstract ideas into functional prototypes. In the optical device landscape, this phase is critical as it involves intricate components such as lenses, sensors, and intricate assembly mechanisms. A streamlined prototyping process ensures that every facet of the optical device is thoroughly evaluated, refined, and optimized before moving into mass production.

Challenges Encountered in Prototyping Optical Devices

Complex Design Requirements

The intricacy of optical devices presents unique challenges in prototyping. Precise optical characteristics, including focal lengths, refractive indices, and dispersion properties, demand sophisticated manufacturing techniques to achieve the desired performance. Balancing these technical requirements with feasibility during prototyping is a significant challenge.

Iterative Development

Optical devices often require iterative design improvements to achieve optimal performance. Each iteration demands meticulous adjustments and testing, extending the prototyping phase. Optimizing this iterative cycle without compromising quality is pivotal in expediting the prototyping process.

Material Selection and Compatibility

Selecting suitable materials is crucial for optical device prototyping. The compatibility of materials with optical elements, such as lenses, coatings, and substrates, significantly impacts device performance. Identifying materials that offer the right balance of optical properties, durability, and manufacturability is a crucial consideration.

Strategies for Optimizing Prototyping Processes

Advanced Simulation and Modeling

Leveraging advanced simulation tools and modeling software can significantly expedite the prototyping phase. These tools enable designers to simulate optical behaviors, predict performance outcomes, and refine designs before physical prototyping. Virtual testing minimizes the need for multiple physical iterations, thereby reducing time and resource expenditure.

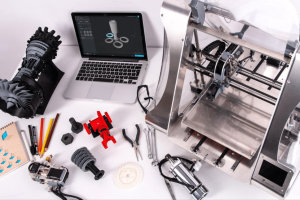

Rapid Prototyping Technologies

Incorporating rapid prototyping technologies, such as 3D printing, micro-machining, and laser cutting, accelerates the fabrication of intricate optical components. These techniques allow for swift iteration, enabling designers to quickly validate designs, assess tolerances, and identify potential issues early in the process.

Collaboration and Integration

Encouraging seamless collaboration between design, engineering, and manufacturing teams streamlines the prototyping process. Ensuring open communication channels fosters a collective understanding of design objectives, accelerates decision-making, and minimizes discrepancies between design intent and manufacturability.

Material Exploration and Testing

Conducting thorough material exploration and testing during the prototyping phase is crucial. Exploring new materials and coatings that align with optical requirements while ensuring ease of manufacturing can enhance the efficiency and performance of the final product.

Metrics and Continuous Improvement

Key Performance Indicators (KPIs)

Track metrics such as:

- Iteration Cycle Time: Average time from CAD to tested prototype.

- Yield Rate: Percentage of prototypes meeting design specifications.

- Cost per Iteration: Material and labor cost breakdown.

- Defect Discovery Rate: Number of design flaws found per prototype.

Feedback Integration

Regularly review KPI trends in project retrospectives. Identify bottlenecks—whether design, manufacturing, or testing—and implement corrective actions:

- Invest in faster 3D printers or on-site polishing.

- Automate optical alignment checks with camera-based systems.

- Train teams on new CAD-simulation integration tools.

Continuous process improvement fosters a culture of innovation and rapid learning.

Case Study: Virtual Reality Optics Startup

A small VR optics startup cut prototyping time by 50% using these methods:

- Digital Simulation: Validated lens designs in silico before printing.

- 3D-Printed Housings: Developed and tested ergonomic headsets in days, not weeks.

- Parallel Runs: Printed three lens-curvature variants simultaneously, selecting the best performing one for final machining.

The company launched its first product six months faster than its initial schedule, securing a critical first-mover advantage in the VR market.

Future Trends in Optical Prototyping

Photonic Integrated Circuit (PIC) Prototyping

Advances in silicon photonics will drive the need for rapid prototyping of integrated optical chips, requiring new micro-fabrication and packaging methods.

AI-Assisted Design and Testing

Machine learning algorithms can predict optical performance from limited prototype data, suggesting design tweaks before physical fabrication.

On-Demand Custom Optics

Cloud-based ordering platforms will connect designers to global networks of micro-fabricators, enabling one-to-one customized lens orders delivered in days.

Conclusion

Optimizing prototyping processes is essential for achieving optical device innovation in today’s fast-moving market. By combining digital simulation, rapid manufacturing, iterative testing, and cross-functional collaboration, teams can compress development cycles, reduce costs, and improve final product quality. Modular design, standardized documentation, and lean workshops further streamline workflows, while clear KPIs drive continuous process improvement. As new technologies like silicon photonics and AI-assisted testing emerge, these best practices position optical developers to stay ahead of the curve. Embrace these strategies to refine your prototyping pipeline and turn groundbreaking optical concepts into market-ready devices—faster than ever before.

Optimizing prototyping processes in the realm of optical device manufacturing is indispensable for bringing innovative concepts to fruition efficiently. By embracing advanced technologies, fostering collaboration, and prioritizing material exploration, manufacturers can streamline prototyping, reduce time-to-market, and deliver high-quality optical devices that meet and exceed consumer expectations. An integrated approach that merges design ideation with efficient manufacturing practices is the key to unlocking the full potential of optical innovation.